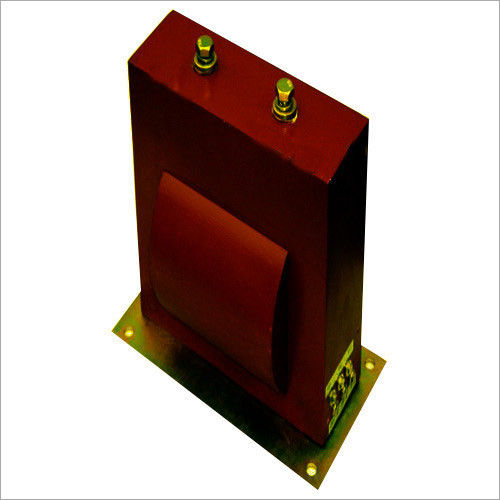

Current Transformers

Current Transformers Specification

- Capacity

- 5 VA - 30 VA

- High Voltage

- 0.72 kV

- Dimension (L*W*H)

- 110 mm x 80 mm x 45 mm

- Operating Temperature

- -10C to +55C

- Cooling Type

- Air cooled

- Rated Voltage

- Up to 0.72 kV

- Standard

- IS 2705, IEC 61869-2

- Voltage Booster Type

- Does not apply

- Coil Material

- Electrolytic copper

- Load Loss

- Low

- Low Voltage

- 0.4 kV

- Product Type

- Current Transformer

- Material

- Epoxy resin and copper

- Output

- 5A or 1A standard

- Frequency (MHz)

- 50 - 60 Hz

- Efficiency

- 99%

- Phase

- Single & Three Phase

- Usage

- Electrical current measurement and monitoring

- Coil Structure

- Encapsulated

- Coil Number

- Primary and Secondary

- Power Scope

- Up to 5000A

- Weight

- Approx. 1.5 kg

- External Finish

- Moulded epoxy resin

- Accuracy Class

- 0.2, 0.5, 1.0, 3.0

- Storage Temperature

- -25°C to +70°C

- Primary Current Ratio

- Varies (Typical Range: 50/1 to 5000/1)

- Insulation Class

- Class B or Class F

- Mounting Type

- Clamp-on/Busbar/Panel Mounted

- Environmental Protection

- IP 30

- Connection

- Screw terminals

- Response Time

- Instantaneous

- Dielectric Strength

- 3 kV for 1 minute

Current Transformers Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cash Advance (CA), Western Union, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

About Current Transformers

Fostered with a team of highly experienced professionals, we are offering our clients a superior quality assortment of 11KV CT PT Combined Unit. Requires less maintenance, user friendliness, easy to operate, shock proof and corrosion resistance are some qualities of given range. Our offered products are accessible in different technical specifications for protecting different electrical equipment from getting damaged. Further, we offer this 11KV CT PT Combined Unit to the clients at affordable rates.

Product Details

| Insulation Level | 36/70/170 kVP |

| Insulation Level (kv) | 36/70/170KVP |

| Phase | 3 Phase 4 Wire |

| Power (kw) | 100VA |

| Core Type | 33kv Outdoor Ct Pt Unti |

| Voltage (kv) | 33KV |

| Frequency (Hz) | 50 |

| Cooling Type | Outdoor Type |

| Power Source | 36KV HSV |

| Coil Number | 3 NOS CT 1 NOS PT |

| Brand | EREVA ABB CROMPTON SCHNEIDER SIEMENS L&T |

| Material | 33KV CT PT UNIT |

| Voltage | 22KV 33KV CT PT UNIT |

| System Frequency | 50Hz |

Robust Construction and High Reliability

Designed for demanding environments, these current transformers utilize moulded epoxy resin and electrolytic copper windings for durability and superior electrical performance. The encapsulated coil structure protects internal components, facilitating a long operational life and minimized load losses even in challenging industrial settings.

Precision Measurement Capability

Accuracy classes from 0.2 to 3.0 ensure precise current measurement for both metering and protection applications. Instantaneous response time enhances monitoring reliability, while primary current ratios up to 5000/1 make them suitable for a wide range of electrical loads and power distribution setups.

Flexible Mounting and Easy Installation

These transformers accommodate clamp-on, busbar, or panel-mounted installation, offering versatility for various operational scenarios. Equipped with robust screw terminals and standardized dimensions (110x80x45 mm), they facilitate straightforward integration into new or existing systems.

FAQs of Current Transformers:

Q: How are these current transformers typically installed in an electrical system?

A: Installation methods include clamp-on, busbar, and panel mounting. Their compact, standardized dimensions and screw terminal connections make integration with new or existing single-phase or three-phase systems straightforward.Q: What are the benefits of using epoxy resin and electrolytic copper in construction?

A: Epoxy resin ensures high dielectric strength, UV resistance, and moisture protection, while electrolytic copper windings offer superior conductivity and minimal load loss, enhancing the transformers reliability and efficiency.Q: When should I select a specific accuracy class (e.g., 0.2, 0.5, 1.0, 3.0)?

A: Accuracy class selection depends on your applications requirements. For precise metering, choose a lower class value (0.2 or 0.5). For general monitoring or protection, higher classes (1.0 or 3.0) may suffice.Q: Where can these current transformers be used?

A: They are ideal for industrial plants, power distribution panels, switchgear, and commercial buildings in both indoor and protected (IP30) environments, complying with IS 2705 and IEC 61869-2 standards.Q: What is the process for selecting the appropriate primary current ratio?

A: Determine the maximum expected system current, then select a transformer ratio (e.g., 100/1, 2000/1) that matches the application. This ensures accurate monitoring without overloading the device.Q: How does the environmental protection rating (IP30) impact usage?

A: IP30 protection ensures adequate safeguarding against solid objects over 2.5 mm, making the transformers suitable for indoor installations but not for exposed or harsh outdoor environments.Q: What are the main usage and efficiency advantages of this current transformer?

A: These units provide highly efficient (99%) current measurement for up to 5000A, exhibit low load loss, and are optimized for fast, reliable operation in critical power monitoring and metering applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Current Transformers Category

current transformers and voltage transformers

Price 200000.00 INR

Minimum Order Quantity : 1 Unit

Coil Structure : Other, Toroidal / Wound Core

Coil Number : Other, Dual / Multi Coil

Product Type : Other, Current Transformer / Voltage Transformer

Phase : Other, Single Phase / Three Phase

Outdoor Current Transformer

Coil Structure : Toroidal

Coil Number : Other, Single / Multiple

Product Type : Other, Outdoor Current Transformer

Phase : Single Phase

Indoor Resin Cast Current Transformer

Price 8500 INR

Minimum Order Quantity : 1 Unit

Coil Structure : Other

Coil Number : Other

Product Type : Current Transformer

Phase : Single Phase

Indoor Resin Cast Current Transformer

Price 45000 INR

Minimum Order Quantity : 1 Unit

Coil Structure : Other

Coil Number : Other

Product Type : Other

Phase : Single Phase

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry